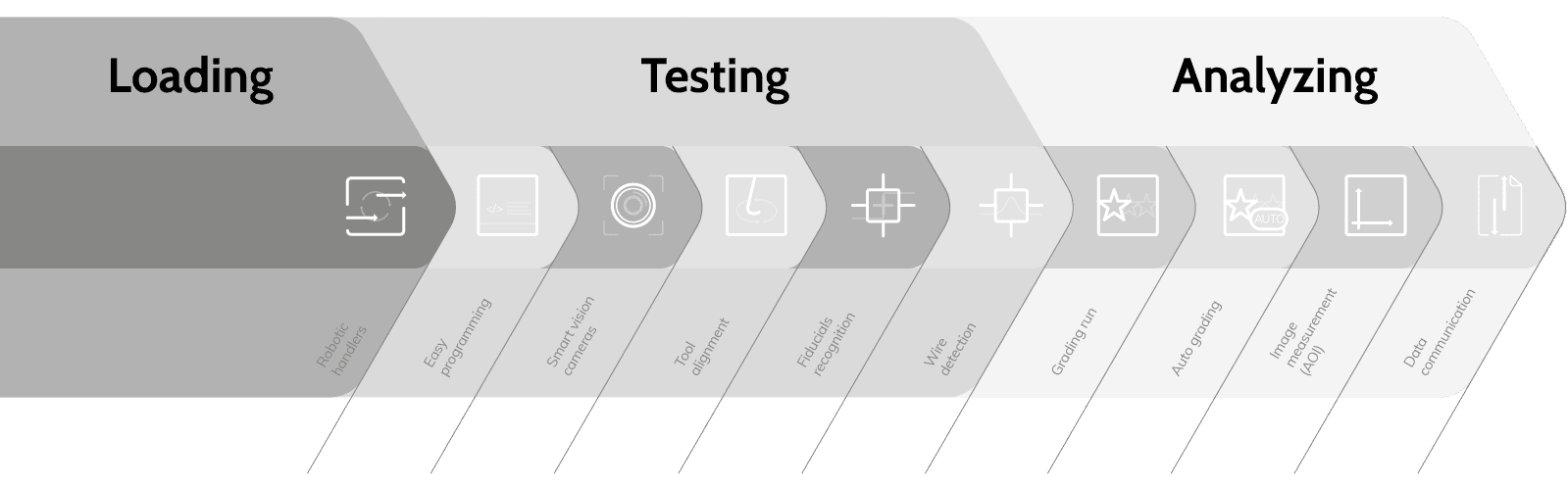

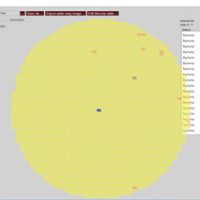

The open Sigma software enables easy programming of total automation steps, positions, and commands. The automation editor employs camera visualization and intelligent wizards.

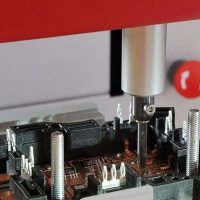

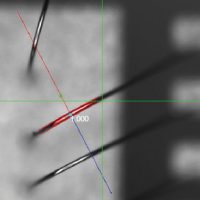

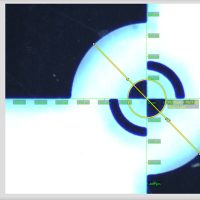

Precise tool alignment is essential to test the correct bonds correctly. Concentricity correction achieves tool eccentricities less than 5 µm, and unique tool designs can be of help during alignment. We offer solutions in customized hook foot lengths or a self-aligning shear tool, which corrects for any tiny but important angular difference between tool and sample. Using the camera and deep access tooling allows you to test complex sample architecture. Switch between different tools in seconds with our unique rotating 6-in-1 test head RMU.

Define recognizable shapes, patterns, or marks as a global or local reference for positioning and automatic tool alignment.

Make sure your sample is in position to test the correct bonds. Fiducials help to correct for any displacements. With camera visualization, it is easy to define recognizable shapes, patterns, or marks as a global or local reference.

Recognition of components and fine pitch wires that are swept out of position due to process tolerances or part handling.

Teach the exact position between the first and second bond using camera visualization and the AOI editor. Simply correct missing wires or recognition problems during the automation cycle or after via extensive reports.

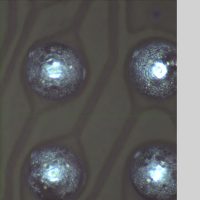

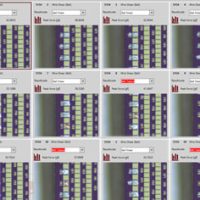

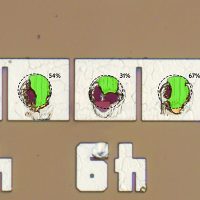

Many leading manufacturers automatically grade the failure modes of the test result images. For ball shear, smart optical inspection algorithms calculate the percentage of the remaining bond material in the region of interest and identify the failure mode using classifications. You can also automatically grade other types of bond failures.

Operators do not need to fulfill assessments by accepting or editing the failure modes at the end of an automation run. With machine vision software and deep learning, we train a neural network to do the image processing for you. By classifying the failure mode criteria beforehand, image recognition is ready to perform automatic grading without any assistance.

Automatically store the reports after several measurements. The editor supports export to file, serial port, clipboard, and other protocols such as SECS/GEM.

SECS/GEM is an equipment interface protocol for equipment-to-host data communications in the semiconductor industry. Several xyztec customers use the bi-directional SECS/GEM capability of the Sigma for test results, images, recipes, and other data.

Sigma bond testers are fully GEM300 compliant, ushering in a new era of manufacturing efficiency with seamless communication and automation between bond testers and production equipment, ideal for automated lead frame and wafer testing.

Local support and parts, global presence, world-class testers

Netherlands

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Germany

Am Haupttor / Bürocenter

06237

Leuna

Germany

USA

170 Commerce Way

Suite 200

Portsmouth, NH 03801

United States

72/7 M.12 Soi. Soonthornwipak

Bangpla, Bangphli,

10540 Samut Prakan

Thailand

No. 157, Zhongzheng

6th St., Hukou

Township, Hsinchu

County 303,

Taiwan (R.O.C.)

Room 2012

Haichuang Mansion,

No.288 Dengyun Road,

High-tech district, Kunshan,

Jiang Su, China

Contact your

local

representative

Xyztec develops world-class bond testing technologies and works together with global partners to provide local support worldwide.

J.F. Kennedylaan 14b

5981 XC

Panningen

The Netherlands

Tom Haley