Whilst many things can affect the force measurement accuracy of a bond test its ultimate limitation is that of the force sensor. For this reason alone and with no cost penalty why would you accept anything but the best? Xyztec has taken accuracy to a new level with its latest range of Sigma bond testers. This market-leading accuracy is also guaranteed without the need to select any force measurement ranges. How do we do it?

The limitation of a bond test is the force sensor measurement

The limitation of the force measurement should be the sensor load cell, sometimes called the transducer. The main cause of error in a load cell is sensitive to temperature. Even small changes in temperature can have a significant and detrimental effect. The previous state of the art was to add hardware to the load cell strain gauge bridge that reduces output changes caused by temperature. This is a difficult procedure that requires the sensitivity to temperature to be measured and then an estimate of the required hardware correction applied.

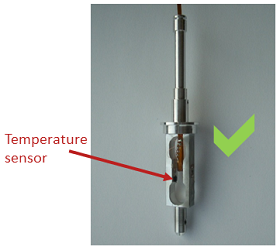

Temperature sensor

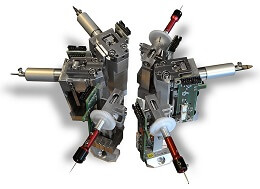

Because of the time taken it is typically done with one iteration and at two temperatures. Leading the industry xyztec has added a temperature sensor to their force sensors. This makes temperature correction much easier and more accurate. The force output is simply measured at a range of standard loads and at a range of temperatures. The systems software then applies a force temperature map removing the uncertainty of estimates, approximations at limited calibration points.

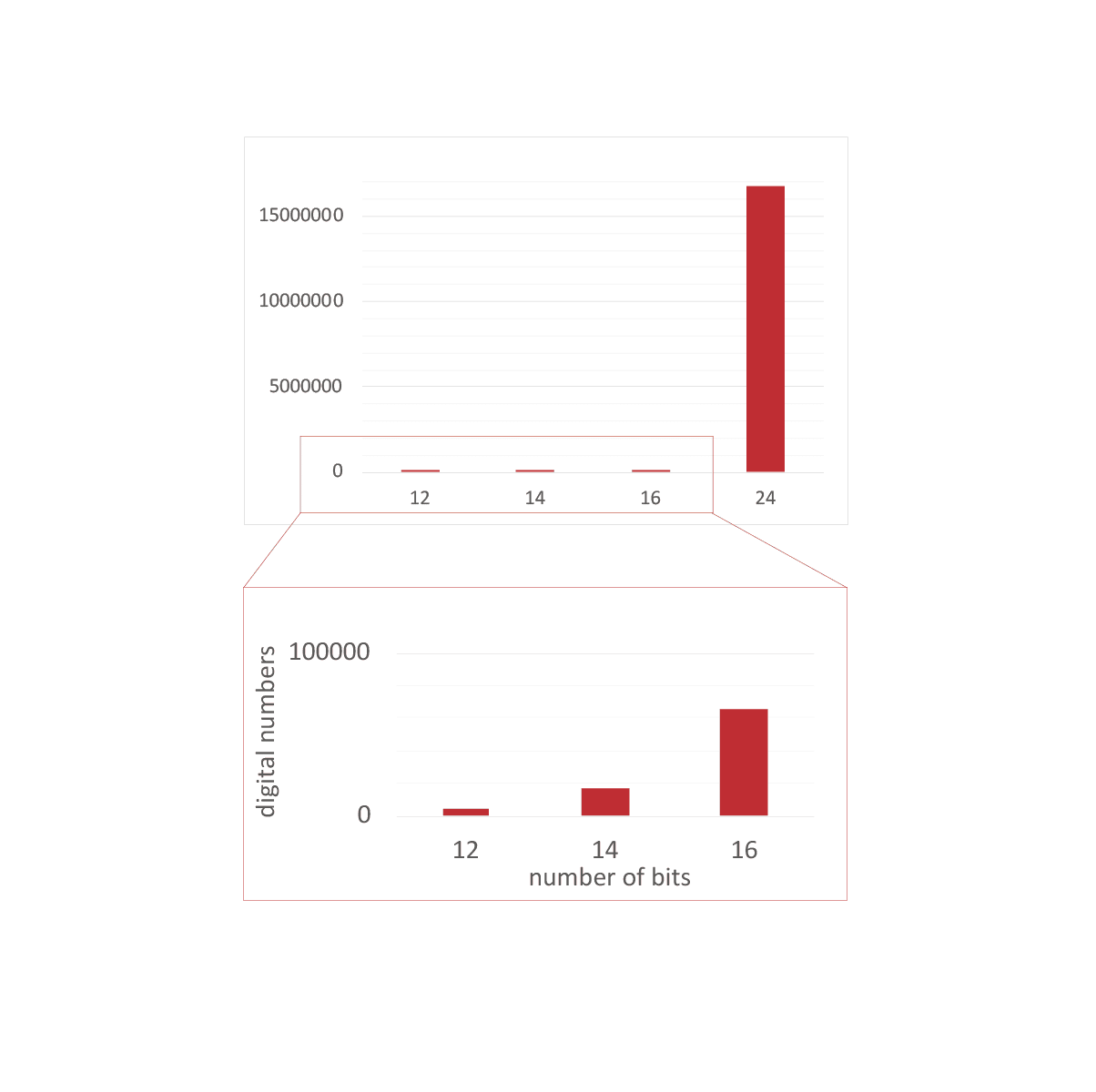

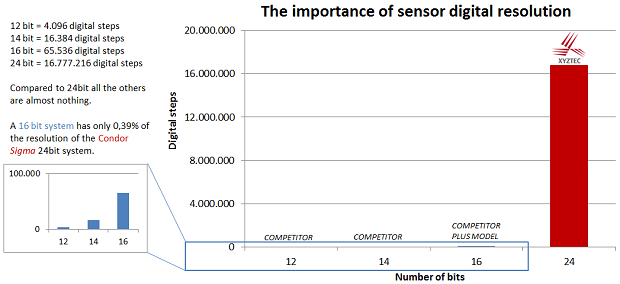

Analogue to Digital Converters (ADC)

Sensor ranges are an invention to overcome limitations in the conversion of the analogue sensor output into a digital one. Less capable Analogue to Digital Converters (ADC) have a resolution less than that of the sensor analogue signal. This means their accuracy is dictated by the ADC rather than the sensor and this is particularly bad when measuring low forces. To overcome this limitation ranges are used. Ranges apply the number ADC steps to typically 100%, 50% or 10% of the sensor output. It is a common misconception that ranges improve accuracy. They do not. They simply limit the negative effect of an insufficient ADC capability.

All Sigma sensors use 24 bit ADC with a digitized resolution of 16,777,216 steps. In comparison, alternative systems use 16 bit and 12 bit with 65,536 and 4,096 step respectively. It can be seen that this difference in digital resolution is really quite massive.

The Sigma with its 24 bit ADC does not need ranges to achieve its specified accuracy of ±0.075%. And its accuracy will be the best you can get when measuring at its maximum or low down in 10% of its full scale.