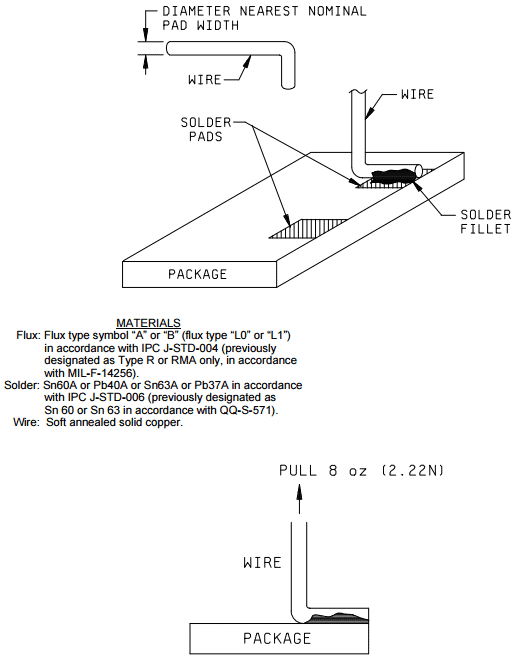

MIL-STD-883 method 2004.7 – Test condition D: Solder pad adhesion for leadless chip carrier and similar devices

Purpose

This test is designed to check the capabilities of the device solder pads to withstand a delamination (peel) stress of specified tension and time.

Apparatus

Equipment for 10X magnification, suitable clamps and fixtures for securing the device and applying the specified tension/time conditions to wires soldered to the device solder pads. Equivalent linear pull test equipment may be used.

Procedure

Unless otherwise specified, a delamination (peel) stress test shall be applied to randomly selected solder pads from each device selected for test. Further, unless otherwise specified, the sampling shall be Sample Size Number = 15, c = 0 based on the number of solder pads tested, chosen from a minimum of three devices. Preparation and testing of devices shall be in accordance with figure 2004-2 of this method and as follows.

- Pretinned soft annealed solid copper wire of a gauge (diameter) nearest, but not exceeding that of the nominal solder pad width, shall be soldered using Sn60A or Pb40A or Sn63A or Pb37A of IPC J-STD-006 (previously known as Sn60 or Sn63 solder in accordance with QQ-S-571) to each solder pad to be tested in a manner such that the wire is bonded over the entire solder pad length and terminates at the package edge (see figure 2004-2). The unsoldered portion of the wire shall be bent perpendicular to the bond plane prior to attachment. Caution should be taken to assure that the solder pad metallization is not damaged during the soldering or the wire bending operation.

- Unless otherwise specified, a minimum tension of 8 ounces (2.22 N) shall be applied, without shock, to each solder pad to be tested in a direction perpendicular to the solder pad surface and maintained for 30 seconds minimum.

Failure criteria

When examined, using 10X magnification, after removal of the tension stress, the appearance of any delamination involving constituent solder pad interfaces shall be considered an adhesion failure of the solder pad. Separation of the solder pad from the device is an obvious (without visual magnification) adhesion failure. Separation of the wire from the solder fillet (leaving the solder pad intact) or wire breakage is considered a test procedure failure.

Summary

The following details shall be specified in the applicable acquisition document:

- Sampling criteria, if other than specified (see 3.0).

- Failure criteria, if other than specified (see 3.1).

- Tension to be applied in this test if other than 8 ounces (2.22 N).

- Length of time tension is to be applied if other than 30 seconds.