Xyztec introduces Battery Module Bond Testing (BMBT)

Building on over 20 years of experience supporting the bond testing needs of many different industries, xyztec is again leading the way by providing unique solutions to support the battery market. There is an increasing demand for testing the interconnects of commercial, personal, and electric vehicle (EV) battery applications. By developing the proper bond schedule, process engineers can be confident that their battery modules are not compromised by bad bonds generated in the bonding process.

Battery market needs dedicated solutions

As the vehicle market moves toward increased commercialization of electronic drivetrain technologies, the need for ensuring battery module reliability is more important than ever. Only through robust mechanical testing of the interconnections between individual battery cells (i.e. wire bonds, ribbon bonds, laser welding tabs, etc.) can manufacturers validate the final construction of battery modules for release and service in the field.

We deliver on market demand

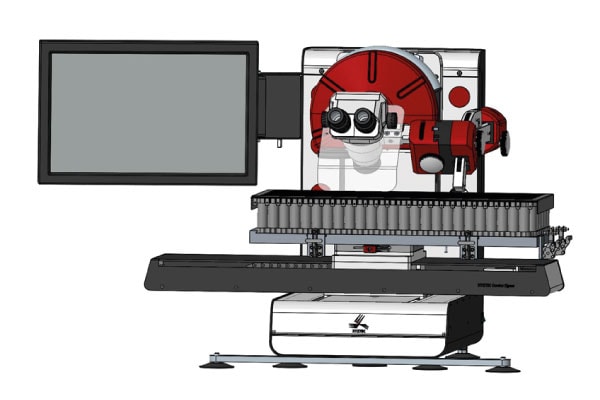

To support this growth in testing demand, xyztec offers multiple equipment platforms that can be configured to enable Battery Module Bond Testing (BMBT): The Sigma, a benchtop solution; and the L/XL series of bond testers, a floor-based system capable of testing the largest battery modules in the industry to date. Even better, xyztec’s team can partner with your engineers to develop customized work-holder solutions for battery modules. Our work-holders provide secure clamping, repeatable positioning of modules, and stability during any bond test.

These systems expand our equipment’s testing capabilities for battery module applications without compromising any of xyztec’s existing toolbox of industry-leading software platforms, visualization tools, and automation solutions. All bond testing systems listed here are capable of both destructive and non-destructive bond testing, along with automated programming of bond test recipes.

The result?

It has never been this easy to apply bond testing to battery modules.

Using xyztec systems, any engineering team working on battery module development and assembly processes can use bond testing to verify the performance of all critical interconnects linking individual cells on a battery module. The results provide a comprehensive understanding of bonding process outputs to ensure production of the most reliable battery bonds possible!

Specifications