Cell phone display and LCD driver IC’s are difficult to shear test. A fundamental problem exists when shear testing large die; the strength of the bond (typically over 100 kgf) is in proportion to the area of the die but the area available to apply the shear load is much smaller being limited to that of one of its edges. This can easily result in die fracture rather than bond failure. In addition the substrate is often very thin and made of brittle materials like glass. If the bond test is not designed correctly this too can fracture before the bond is tested.

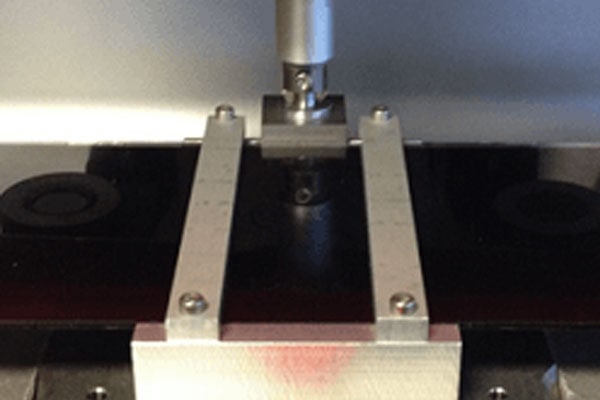

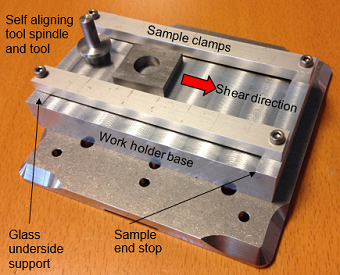

Self Aligning Shear Tool

Xyztec helps you to design the optimal test solution that has the best chance of producing the failure mode of interest. In the case of thin die the xyztec patented Self Aligning Shear tool solves such problems effectively, as demonstrated in this extract from a xyztec application report.

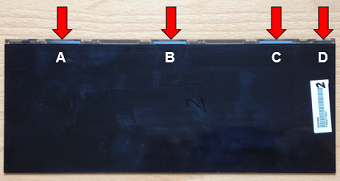

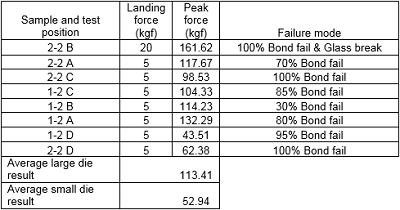

The first test on sample 2-2 position B used a landing force of 20 kgf. This produced 100% bond failure, the highest test result but fractured the glass substrate. This was because the landing force was too high.

In the other tests 5 kgf landing force was used and produced a reasonable percentage of bond failures and no substrate fractures. It was seen that where the die did not separate from the substrate the tool was instead damaged.

In the study a moderately soft tool was used to help distribute the shear load over its contact area with the die. This was found to be too soft resulting in the tool damage and some incomplete bond failures. Therefore, a hard steel or Tungsten carbide was recommended for the self-aligning tool block material. The tool block is held on the tool spindle by vacuum. The test results were as in the table to the left.