Integration transforms the bond tester into a fully automated system. We offer various types of EFEM (Equipment Front End Module) wafer handlers, to combine with a Sigma W12 for operator-free bond testing.

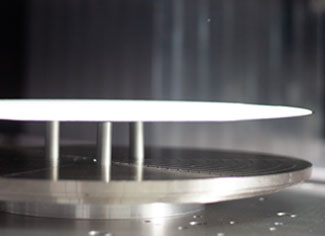

Gently secure flat and warped wafers because of the soft, flexible tips on the PID controlled wafer lift pins. Vacuum sensing and switching are intelligently timed with the lift pin position throughout the load, clamp, and unload cycle.

In cases of extreme warpage, an optional wafer pusher ensures precise clamping. The high airflow of vacuum chucks pulls down wafers.

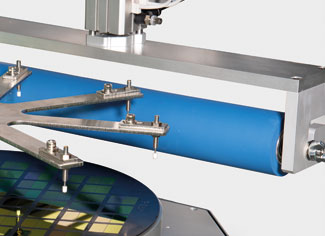

Keep test debris away from the wafer or the wafer chuck with a blower and vacuum cleaner or a roller with sticky foil, for pre- and post-cleaning.

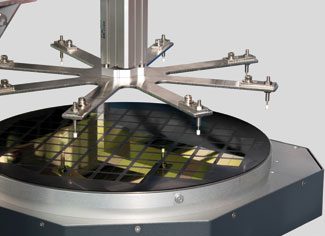

Vacuum work holder for panels or wafers up to 300 mm. Easily reach 100% of a 300 mm panel without repositioning your sample on the chuck. The wafer chuck work holder comes with safety interlocks and 360° rotation.

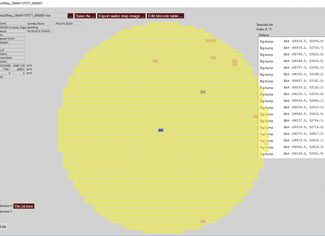

Easily import and export multiple file formats for wafer maps such as KLARF, (S)INF, G85, and others for full traceability. Defects or test positions are shown in an overview and are directly accessible for testing or analysis.

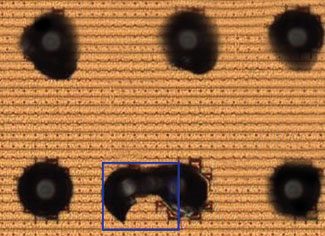

Automatically shear the big bumps and clean the debris to prepare for wafer probing. Fully programmable vision algorithms can check if the removal of big bumps was successful.

Dirk Schade