This newsletter describes the best way to shear test the solder on copper pillars. Xyztec has a lot of experience with different types of copper pillar products and can also advise you on cold bump pull testing of the same solder bumps and 2 separate ways to test the copper to pad interconnect.

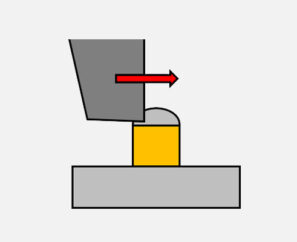

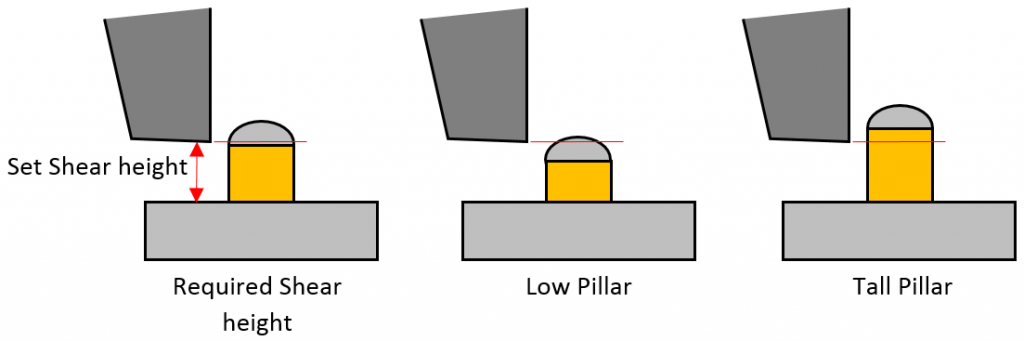

Accurate shear height control when shearing the solder bump

As with any shear test, testing the solder to copper interconnect requires accurate alignment of the shear tool to the bond line. When the height of the bond line from the substrate varies due to tolerance build up conventional shear height methods can be a problem.

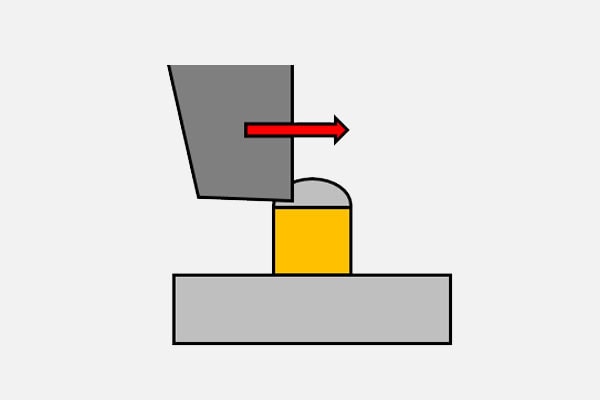

A solution is xyztec’s unique top landing shear method. The tool lands on the top of the solder, then moves back and down programmable amounts to guarantee a shear height relative to the top of the pillar rather than its base.

The video below shows a test. The programmed landing force is 5gf. As the landing contact is initially a point, even with a low landing force, a small amount deformation occurs on the top of the solder. The loads on the pillar bond though are small and compressive and have no detrimental effect on the measurement. The Sigma is the only bond tester in the world with a programmable landing force and is capable of lower landing forces than any other tester.

About xyztec

Xyztec is market leader in bond testing. We continue to develop solutions for all types of industries including solar, space, military, medical, automotive, interconnect and material science. Our customers include market leaders in all of these industries throughout the world. Owning the best quality assurance tells your customers what you priorities are. Request a live demonstration of the Sigma on your sample and contact us today!