As the forerunner in automatic bond testing, xyztec comes with very promising functionalities to grade failure modes without any assistance for ball shear and wire pull tests. Read more about auto grading developments and 2 new systems: the sliding battery work holder and the Sigma Loadport for magazines. Are you ready to automate your processes?

Automatic grading without any assistance

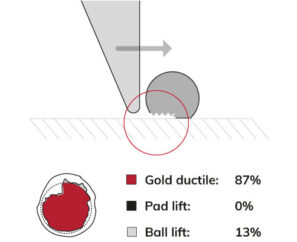

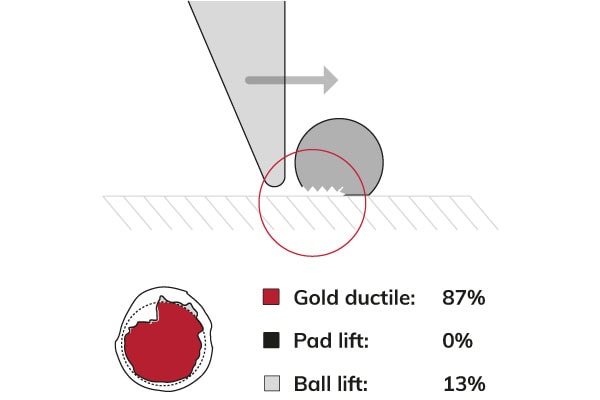

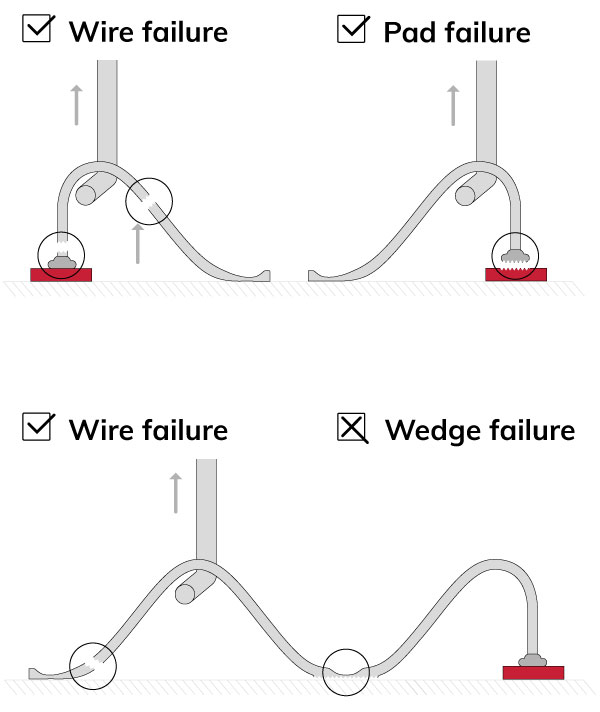

Fully automatic loading and testing on a Sigma bond tester have been possible for years. However, automatic analysis without operator intervention remained a challenge. Using deep learning, we now got this covered! A Sigma can automatically determine the failure modes on samples, removing the need for operator grading on your parts.

How does it work?

Deep learning automatically determines the failure modes of the test result images. The system learns features that allow the classifier within the algorithm to distinguish between failures. The test target features are taught by training a neural network in image processing. Operators do not need to fulfill assessments by accepting or editing the failure modes at the end of a fully automatic run.

Does it work on my sample?

The current algorithm already covers numerous different applications, but some applications might require custom work. Auto grading is currently available for ball shear and wire pull tests.

Compact solution for battery modules up to 900 mm

Test entire battery modules without the need to manually rotate the module mid-testing. For this custom solution, we use a Sigma W12 bond tester for 300 mm wafers as a baseline and add a custom sliding work holder that allows fully automatic testing across the entire battery module.

Sliding work holder enables bigger batteries

The custom pneumatic stage extension increases the testable reach in X beyond the standard 600 mm to a maximum of 900 mm. By extending the machine body and mounting the RMU farther from the rest of the system, the Y-axis is now 370 mm, a 120% increase relative to a standard Sigma.

Your module fits, too!

This work holder solution is just one example of our ability to generate custom solutions to meet unique customer requirements. We offer bond test systems for all battery pack sizes, including bench-top and floor model solutions to test heavy applications or battery packs.

Integrate a Sigma MAG in your product line

The Loadport in an extension to the Sigma MAG for automatic (un)loading of magazines up to 100×240 mm without operator intervention. It communicates through SEMI E84 and allows top- and frontloading by:

- Over Head Transport (OHT)

- Automated Guided Vehicle (AGV)

- Or manually

Magazine buffering makes lead frame testing even more efficient. It is possible to load multiple magazines to keep the system running and ensure no down-time on the bond tester.

Compliance to SEMI S2/S8 and GEM 300 improves safety

Like the Sigma MAG, the Loadport comes with a safety enclosure and is compliant to SEMI S2/S8. The frontside of the Loadport is open but has safety light curtains. When the operator reaches through the light curtains, the system shuts down immediately to guarantee optimal safety protection.