Straightforward pull test

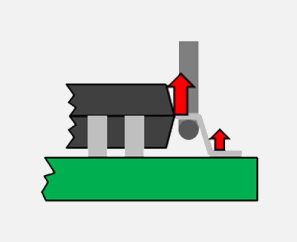

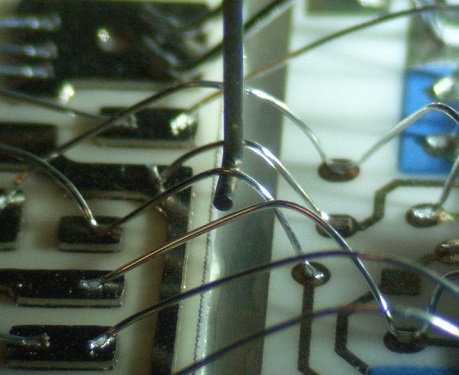

It is possible to do regular pull tests on SMD gull wing leads using a hook. However, there are three problems with that approach, namely:

- There is very little space to get the hook in to pull a lead.

- The body supports the lead being tested.

- When the hook is a tight fit under the lead, in the test method the sensor must not be nulled/zeroed before the test; it must be manually nulled before the alignment.

SMD gull wing leads testing

Because the hook is closer to the package than the pad, a lot of the test load goes into the package rather than the bond of interest. However, a weak lead to pad bond will still give a lower result and failure mode analysis of the tested bond will show poor soldering. A strong wire hook is required. Xyztec can support you with extra strong hooks that will withstand relatively high forces. Despite the fact that a fraction of the test load goes into the package, analysis of the results may still provide meaningful data on the bond of interest.

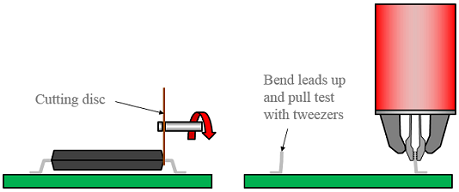

How to test SMD gull wing leads

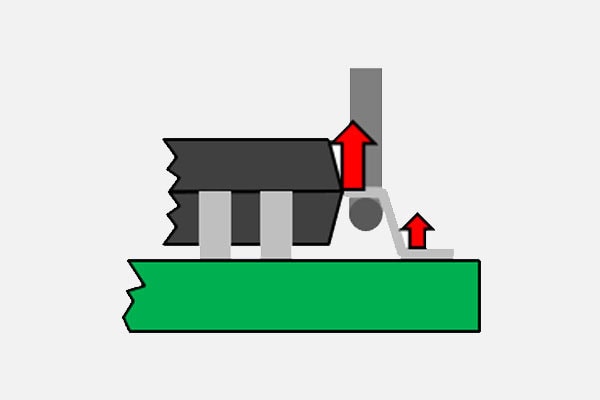

The best way to test the bond of an SMD gull wing lead is to cut the body from the leads and then test each lead with a tweezer pull sensor. This way, the bond is tested with no effects from the body and the other leads. The downside of this approach is the preparation time involved.

Other solutions without cutting the body off

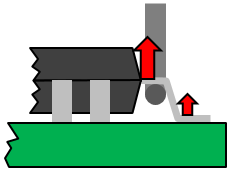

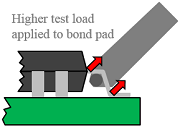

To minimize the effect the body has supporting the bond it may be better to use a vector pull than a regular wire pull, using a special hook and a shear sensor. This also allows the hook to be made stronger but it might still be weaker than the lead, depending on the clearance under the lead for the hook. With a vector pull, a higher test load is applied to the bond pad than with the regular wire pull.

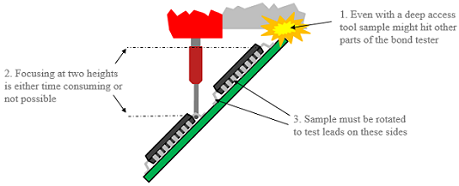

Another method is to incline the sample. Using this approach, one can still use a regular pull sensor in combination with a strong wire hook. This has the following limitations, though:

- It may not be possible with large samples because they hit the bond tester head or frame.

- The Sigma’s large work area does diminish this problem.

- Focusing a microscope at different test heights may not be possible or can reduce the number of tests per hour.

- The Sigma’s EZ microscope support helps to overcome this.

- Sample must be rotated to test all sides of the component.

- Handling and clamping an inclined sample can be difficult.

How to test bonds?

As market leader in bond testing in Europe and Taiwan, xyztec has a lot of experience with many different types of samples and test types. The thoughts in this newsletter on SMD gull wing leads are just one example. We aim to spread knowledge about bond testing in the industry.

We currently offer how-to’s on Cold Bump Pull (CBP) and Wire Pull and we intend to expand it into other test types as well in the future. Additionally, you can find here the text of the relevant MIL-STD-883 standards in accessible HTML format. If you are interested in a live demonstration of the Sigma on your sample or perhaps for more bond testing inspiration, contact us today!

Click here to go to our how-to on Wire Pull

Watch bond testing being automated

Click here to watch our automation video or here to watch the video of the patented CBP Jaw Cleaner.