Loop height

Bond testers are traditionally used for force measurement only, but the extreme positional accuracy of the Sigma platform also enables you to measure whether the dimensions of your product are within specification, with never before seen accuracies. The system is equipped with 30nm resolution linear encoders and is completely backlash free (no gear box).

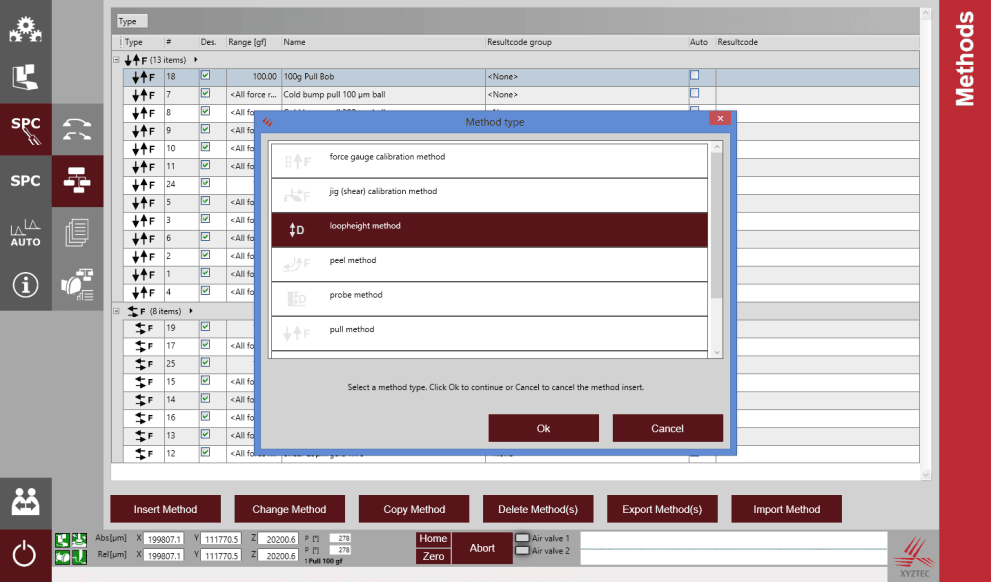

On any Sigma bond tester, the loop height measurement test method is available for free using pull sensors. The system will accurately determine the height of a wire, ribbon or other component above the surface. The measurement result in this case is not a force, but a distance.

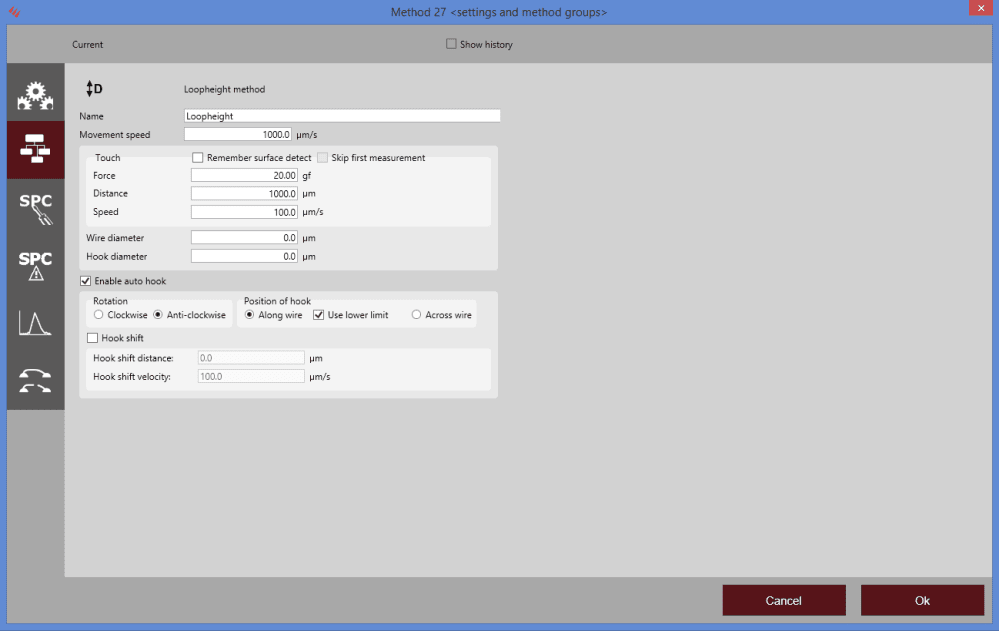

To enable quicker testing, the system can store the Z-height of the surface under the first wire and use this value again when sensing the following multiple wires. It is also possible to probe the surface height in a different spot than directly under the wire.

The operator can combine loop height measurement with a pull test, whether destructive or not. In that case, the loop height distance is simply presented alongside the force measurement result.

As with regular wire pull, it is possible to use the hook shift functionality of the Sigma to position a fine pitch hook accurately under the wire in tight spaces. Auto hook is also available and the loop height measurement test method is of course for both manual and automatic testing.

The Sigma is also unique because of its programmable landing force down to 2,5 gf. Combined with an also programmable probe test speed, this enables very delicate sensing. Deformations or damage to the sample are therefore minimized.

Test features

- Measure wire bond loop heights

- Use your existing pull sensors

- Full statistical analysis with Sigma software

- Available as dedicated method type or as step before a destructive or non-destructive wire pull test

- Hook shift capability to position fine pitch hooks accurately under the wire

- Programmable landing force (down to 2,5 gf) and test speed enable delicate sensing

- Similar to probe testing