Bending

A bending test is designed to check the capability of the leads, lead welds, and seals of the devices to withstand stresses to the leads and seals which might reasonably be expected to occur from actual handling and assembly of the devices in application, or to precondition the leads with a moderate bending stress prior to environmental testing.

Fracture strength of thin wafers and die

There are many types of wafer and die and many different reasons to test them. Your concerns might be stress crack propagation, delamination or the effects of the crystalline structure on strength. Click here to read our article that elaborates on the subtle differences between several types of bend tests 3 point bend test, 4 point bend test, ball and ring test, ring and ring test.

Three point bending test

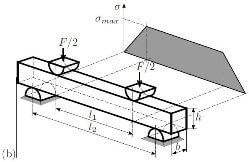

As the name implies, bending tests are carried out to ensure that a substrate (e.g. ceramic, FR4 board or silicon) has sufficient resilience to withstand a specified bend strain. The sample is bent between three or four points to a specified displacement or arc.

For composite materials the bend strength of different reinforcing web patterns and their direction can be investigated.

Data is collected in the form of force versus bend deflection. From this bend curvature, stress and strain can be calculated. In certain FR4 bending applications, parallel to the bending test, the board resistance is measured.

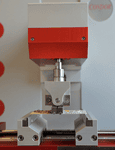

Xyztec is one of the world’s leading manufacturers for testing systems that can be used for dynamic material testing. With a few simple modifications, our Sigma becomes a customized solution for this test.

Four point bending test

Uni-axial bending test

Ultra-thin die with reduced layer thickness enable the high mechanical flexibility required for many new applications. This however increases the demand for manufacturing and testing. The standard shear test can not be used for ultra-thin die, because of their thickness. Analysis of the mechanical resistance to bending before the chip breaks becomes more important.

This analysis can be performed with the xyztec Sigma and the corresponding uni-axial bending test. With this test geometric tolerances and deflection of a chip are taken into account and further customization is possible with the software developed by xzytec. Our company presented this uni-axial bending test for the first time at the Semicon West 2012 in San Francisco.

Vision enhanced analysis

With a special camera mounted on the bond tester, one can visualize deformations during bend tests. Click here to read more about this functionality.

Test features

- Bend strength

- Measurement up to 500kg force

- Thermo cycling

- Sensor accuracy ±0.075%

- More than 200.000 test cycles supported